Nickel Alloys

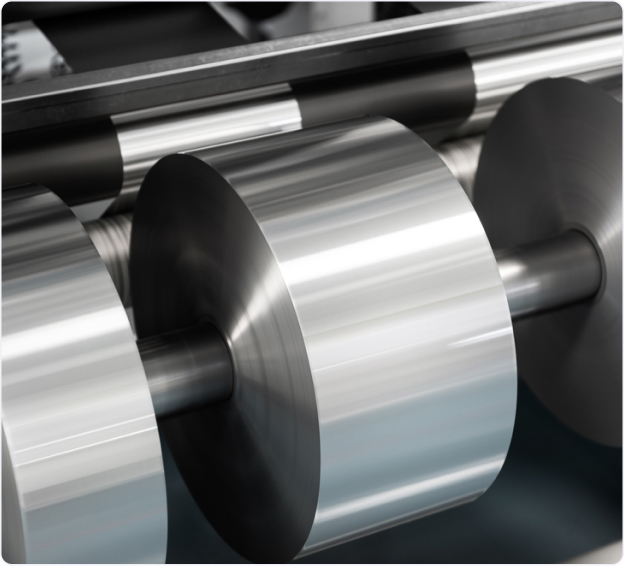

Nickel alloy fasteners are widely used due to their strength and ductility. Nickel superalloys exhibit high strength coupled with high temperature resistance and are used for high stress, high heat applications. Wrought nickel alloys are characterized by their anti-corrosive properties as well as the high strength and temperature resistance properties found in the other nickel alloys. Monel®, Hastelloy® and Inconel® are widely used wrought alloys. While they do produce high strength fasteners, nickel alloy screws, bolts, nuts and studs are difficult to machine and require special handling to avoid work hardening and brittleness.

Common uses for nickel alloy fasteners

- Food processing or food serving equipment

- Marine and saltwater equipment

- Pump and valve components

- Equipment and components exposed to chemicals, acids, and other corrosive materials

- Exhaust systems, engine components, and other high heat equipment.

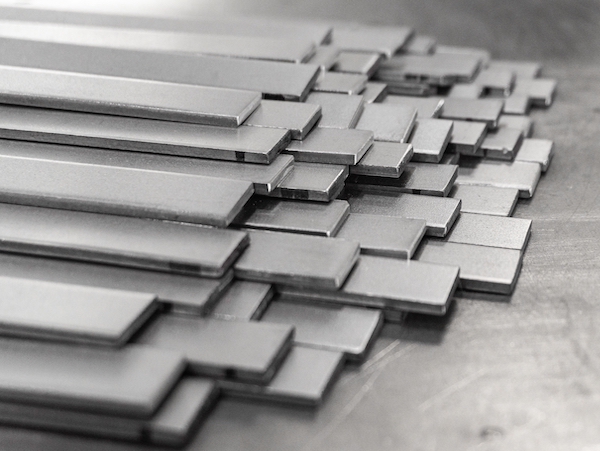

Eastwood manufactures custom fasteners using all grades of nickel alloys. We are experienced in working with metals that are difficult to machine and will accommodate the specific properties of the alloys. We offer full CNC manufacturing and forging production capabilities and can manufacture fasteners with exacting tolerances in non-standard configurations. We offer custom sizes, shapes and thread configurations. Our fasteners are manufactured to MIL-I 45208 standards and we can manufacture to ASTM, SAE, DIN and customer-defined specifications if required.

We are committed to providing each client with a high quality, production-ready fastener. Our staff will work with you throughout production to ensure that your fastener meets your requirements.