Exotic Alloy

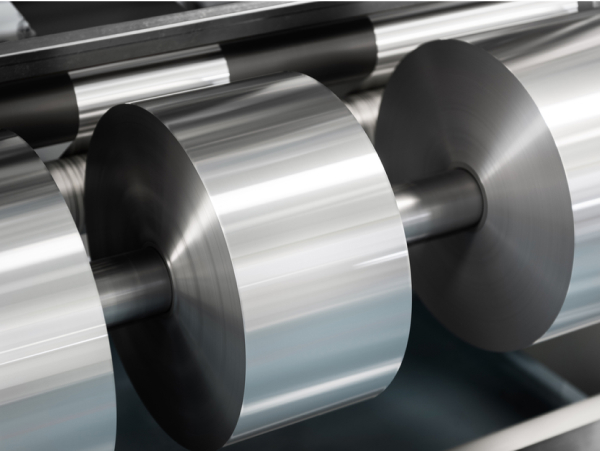

Exotic alloys are used in specialty alloy fasteners that require high performance in extreme environments. Fasteners made from exotic materials perform well in high-temperature, high-stress, and high-corrosion environments. They can also be manufactured to tight tolerances, ensuring an exact fit. Many of these specialty alloy screws, bolts, nuts, and studs must be machined using special processes to prevent work hardening and brittleness that negatively impacts performance.

Eastwood Manufacturing produces custom fasteners

We use the following exotic alloys:

- Titanium – Used for power generation, marine, and military components that require high tensile strength-to-weight ratios, excellent corrosion resistance, and strong performance in high-wear, high-temperature environments. These include frames, landing gear, hydraulic equipment, propeller rigging and heat exchangers.

- Zirconium – Used for components used in high corrosion environments, including nuclear power plants, and high temperature parts for engines and turbines.

- Tantalum – Used for furnace and heat processing components due to its high melting point and oxidation resistance. It is bioinert and is also used for medical implant components.

- Ferralium – Used for chemical and process equipment, as well as manufacturing equipment components, that require high corrosion and high abrasion resistance.

- MP35N – Used for marine and processing equipment components requiring high strength, high wear and extremely high corrosion resistance. These include saltwater and high acid applications.

Eastwood has full CNC machining and forging production facilities, and specializes in working with non-standard materials. Our staff has the experience to accommodate the specific properties of exotic metals, ensuring that your fastener will meet your exact specifications and perform to the highest standards. We can manufacture your fastener to exacting tolerances with custom sizes, shapes, and thread configurations. In addition, our fasteners are manufactured to MIL-I 45208 standards and we can manufacture to ASTM, SAE, DIN and customer-defined specifications.

We are committed to manufacturing the highest quality fasteners. Our experienced staff will work with you from the initial call through delivery of the production-ready product, ensuring your part is made to your exact specifications.

Contact us for a quote for your exotic alloy fastener.