A286 Alloy

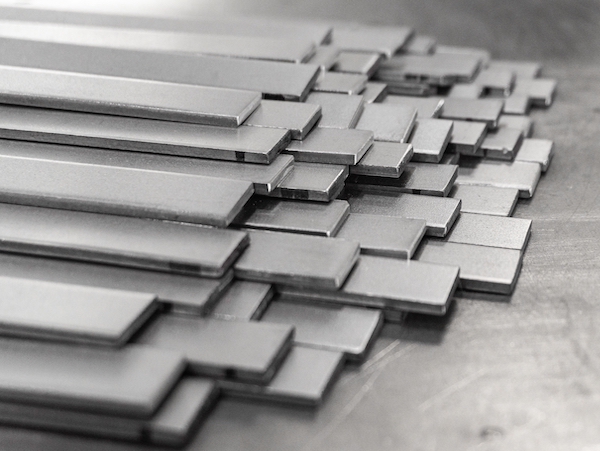

As part of its comprehensive selection of materials, Eastwood Manufacturing offers a broad range of standard and non-standard A286 fasteners. A286 is a durable alloy with advanced precipitation hardening characteristics and is ideal for use in demanding field conditions. Fasteners made from A286 alloys are most often used in the aerospace and petrochemical industries.

The nominal composition

The nominal composition (percentage, minimum to maximum) of standard A286 alloy breaks down as follows:

- Carbon: 0 to 0.08

- Manganese: 0 to 2.0

- Silicon: 0 to 1.0

- Phosphorus: 0 to 0.4

- Sulfur: 0 to 0.3

- Chromium: 13.0 to 16.0

- Nickel: 24.0 to 27.0

- Molybendum: 1.0 to 1.5

- Titanium: 1.9 to 2.35

- Aluminum: 0 to 0.35

- Vanadium: 0.1 to 0.5

- Boron: 0.001 to 0.01

- Copper: 0 to 0.3

- Iron: Remaining balance

Standard A286 alloys display the following typical mechanical properties:

- Tensile strength: 145,000 KSI; 1000 MPa

- Yield strength: 105,000 KSI; 724 MPa

- Elongation: 15%

- Reduction: 25%

- Rockwell hardness: 24 to 37 KSI

These compositional and mechanical properties give A286 alloys outstanding corrosion resistance, along with the ability to maintain high levels of performance even when subjected to extremely high temperatures.

Eastwood Manufacturing is your trusted partner for customized industrial fasteners. We deliver high-performance A286 alloy fasteners at competitive rates, tailored to your application requirements. Reach out to an Eastwood Manufacturing sales representative to find the right solution for your project.