17-4 PH

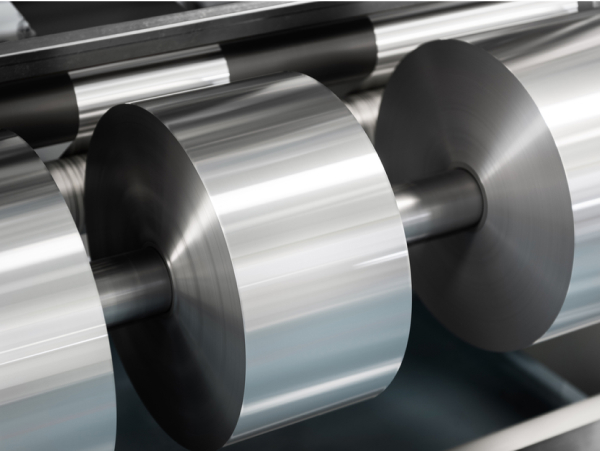

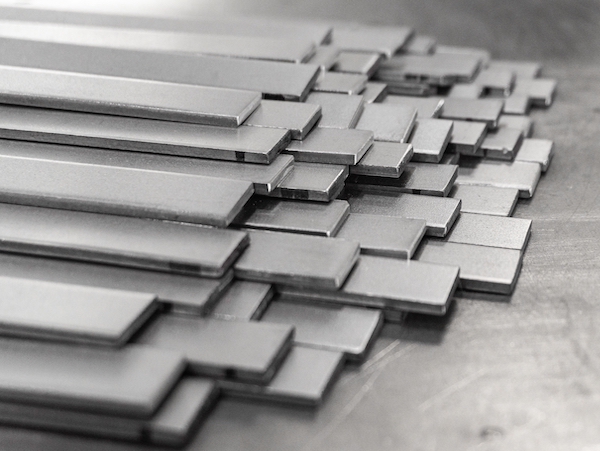

Eastwood Manufacturing’s complete selection of materials includes 17-4 PH (precipitation hardening) stainless steel. Also known as Type 630, 17-4 PH stainless steel is a cost-effective solution for applications demanding high strength and moderate-to-high levels of corrosion resistance. If you require these characteristics in either standard or non-standard industrial fasteners, Eastwood’s capabilities will allow you to take full advantage of this durable yet cost-effective stainless steel.

Properties of 17-4 PH Stainless Steel

Properties of 17-4 PH Stainless Steel include:

- Maintenance of strength and hardness characteristics in temperatures as high as 572 degrees Fahrenheit (300 degrees Celsius)

- Yield strength of up to 1,100 to 1,300 MPa (160 to 190 ksi) with treatment

- Corrosion resistance equivalence of Alloys 304 and 430

While 17-4 PH stainless steel resists corrosion more effectively than any other standard type of hardenable stainless steel, it should not be used in applications involving exposure to very low extremes of temperature. 17-4 PH stainless steel is most commonly used in the following industries:

- Offshore industrial

- Pulp and paper

- Food processing

- Aerospace

- Mechanical

- Nuclear waste disposal

At Eastwood Manufacturing, our sales and production teams are able to quickly and cost-effectively fill custom orders for non-standard industrial fasteners. Whether you require a unique fastener for a demanding application or simply need to refill your fastener inventory, Eastwood promptly fills orders of all sizes and provides products that meet the most demanding performance and quality specifications.

To learn more or inquire about pricing for your project, contact an Eastwood Manufacturing sales representative today.