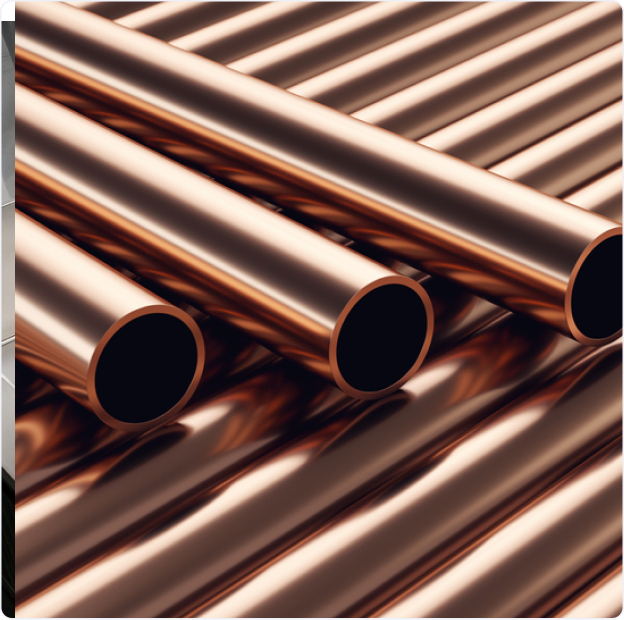

Copper Alloys

Copper alloys include a wide range of copper, brass, and bronze materials. Custom copper fasteners are a popular choice in industrial applications thanks to their strength, corrosion resistance, conductivity, and natural antimicrobial properties. Brass alloys contain zinc, which increases strength but may decrease corrosion resistance. Bronzes are often combined with aluminum, silicon and phosphor to increase strength and corrosion resistance. Brass and copper are used for decorative fasteners due to their shiny finish. Copper, brass and bronze alloy screws, bolts, nuts and studs are easy to machine and, when cold-headed, extremely strong.

Copper Alloy Fasteners for a Wide Range of Applications:

- Electrical components

- Components in marine and corrosive environments.

- Sanitary and medical equipment

- Processing equipment for high wear processes and corrosive environments

- Decorative fasteners for architectural, plumbing, and marine applications

Eastwood manufactures high quality custom fasteners using copper, brass, and bronze alloys. We can manufacture your fastener to exacting tolerances with custom sizes, shapes, and thread configurations. We’re experts in working with non-standard materials, with proven experience machining and forging metals that require special handling or have unique properties. You can be assured that your copper alloy fastener will meet your exact application requirements and perform well. In addition, our fasteners are manufactured to MIL-I 45208 standards and we can manufacture to ASTM, SAE, DIN and customer-defined specifications if required.

We are committed to manufacturing the highest quality cooper alloy fasteners, and our experienced staff will work with you from your initial call through delivery of a production-ready product to ensure that your part is manufactured to your exact specifications.

Contact us for a quote for brass, bronze, and copper alloy fasteners.

| C11000 | ETP Copper |

| C17300 | Beryllium Copper |

| C23000 | Red Brass |

| C26000 | Cartridge Brass 70/30 |

| C27000 | Yellow Brass 65% |

| C36000 | Free Cutting Brass |

| C46400 | Naval Brass |

| C51000 | Phosphor Bronze |

| C61400 | Aluminum Bronze |

| C62400 | Aluminum Bronze |

| C63000 | Nickel Aluminum Bronze |

| C63400 | Aluminum Bronze |

| C65100 | Silicon Bronze |

| C65500 | Silicon Bronze |

| C67500 | Manganese Bronze |

| C93200 | Bearing Bronze |

| C70600 | Copper Nickel 90/10 |

| C71500 | Copper Nickel 70/30 |