Quality

Welcome to Our Quality Department

Your Assurance of Excellence in Machining

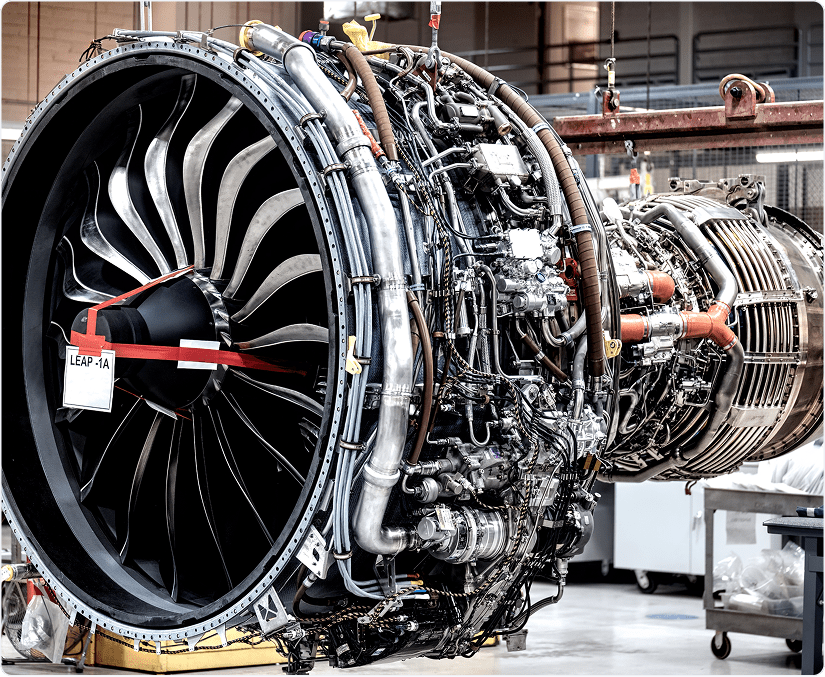

At Eastwood Manufacturing, we recognize that quality is not just a target—it’s our unwavering commitment. As a fully certified ISO 9001:2015 and AS9100D machine shop, we maintain the highest standards within our quality department to ensure that every part we produce meets the rigorous requirements of the aerospace and general manufacturing industries.

Why AS9100 and ISO 9001 Certification Matters

AS9100 Certification

This standard is specifically tailored for the aerospace industry, encompassing every aspect of quality management systems (QMS). Achieving AS9100 certification signifies:

Rigorous Process Control

Detailed procedures to monitor and control processes, ensuring consistency and reliability throughout production.

Risk Management

Proactively identifying and mitigating risks associated with our manufacturing processes, leading to fewer defects and recalls.

Customer Satisfaction

A strong focus on meeting customer requirements and enhancing satisfaction through continuous improvement.

ISO 9001 Certification

ISO 9001:2015 is the international benchmark for QMS applicable across various industries. Our compliance ensures:

Streamlined Processes

A robust framework for optimizing processes, resulting in increased efficiency and reduced waste.

Data-Driven Decisions

An emphasis on gathering and analyzing data to inform decisions that enhance our operations and quality outcomes.

Continuous Improvement

A culture focused on ongoing enhancement, allowing us to adapt to evolving customer needs and market conditions.

Our State-of-the-Art Metrology Equipment

To guarantee the highest standards of quality, we utilize state-of-the-art metrology equipment from well known companies such as Mitutoyo and Keyence. These advanced tools enable us to perform precise measurements and inspections, including:

Coordinate Measuring Machines (CMMs)

For accurate dimensional checks of complex geometries.

Optical Measuring Systems

To ensure surface finishes and dimensions meet exact specifications.

Height Gauges and Calipers

For precise measurements of part dimensions during various stages of production.

This cutting-edge equipment allows our quality team to maintain rigorous standards and ensure that every component we produce adheres to specifications.

Our Quality Control Processes

ISO 9001:2015 is the international benchmark for QMS applicable across various industries. Our compliance ensures:

Incoming Material Inspection

All raw materials are subjected to rigorous examination before entering our production line. Utilizing our advanced metrology equipment, we ensure that every component meets our high standards.

In-Process Inspections

Throughout the manufacturing process, our quality team conducts regular inspections, which include:

- Dimensional Checks: Using our Mitutoyo and Keyence equipment to verify specifications accurately.

- Visual Inspections: Identifying surface imperfections or defects that could impact functionality.

- Process Audits: Regular reviews of machining processes to ensure compliance with established procedures.

Final Product Testing

Before shipping, every product undergoes final inspection and testing, including:

- Functional Testing: Ensuring parts operate as intended under simulated conditions.

- Documentation Review: Verifying that all necessary certificates and reports are included with the shipment.

Our Commitment to Continuous Improvement

Employee Training

Regular training sessions to enhance the skills and knowledge of our team, ensuring they are equipped to maintain our quality standards.

Customer Feedback

Actively seeking and analyzing customer feedback to identify areas for improvement and innovation.

Internal Audits

Conducting regular audits of our processes and systems to identify opportunities for enhancement.